Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

1. The introduction

The mercerizing machines used in mercerizing process include clip mercerizing machine, straight roll mercerizing machine, bent roll mercerizing machine, etc., among which the clip mercerizing machine is widely used, which is composed of two sets of clip chains on the left and the right, the fabric is held by the clip to wash out the alkali and expand the width, the width is easy to control, and the fabric can get a better shrinkage rate.

The clip mercerizing machine, like other dyeing and finishing machines, is composed of many general devices and unit machines, such as feeding device, rolling car, stretching roller, clip drawing machine (mercerizing machine), washing machine, drying machine, cloth discharging device and so on. The control system adopts multi-unit AC frequency conversion speed regulation, which is driven by AC motor for amplitude modulation, alkali absorption, spray and lye recovery, and driven by torque motor for edge detection, water washing machine and upper cloth guide roller. The core of the control system is to drive the left and right clip chains of the mercerizing machine independently, realizing position synchronization while following the speed.

2. The overall WinMO solution and its advantages

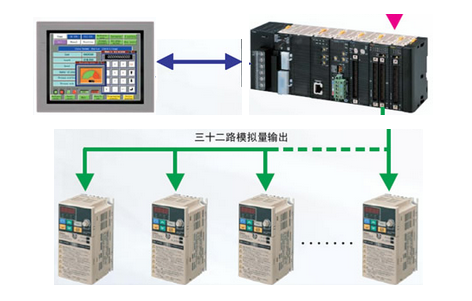

The control system of clip mercerizing machine adopts the medium WinMO PLC DPH60Y24R of Lewei Company as the control core. The driving part adopts WinMO non-inductive vector frequency converter VFT frequency converter. The control of constant speed and constant tension is realized through the analog output control of PLC. And use 10.4 "WinMo PSM071WA touch screen for parameter setting, display and other operations and system monitoring.

Fig. 1 drawing and setting machine process flow chart

3. System configuration

1. The PLC: DPH

High speed processing, LD command execution speed only 100ms

Super-small design, height is only equivalent to the width of a business card

No bottom plate is needed to combine various units with higher efficiency

Seamless Link of three networks (DeviceNet, Controller Link, Ethernet), information remains visible throughout the process

Use large capacity CF card as memory card, simplify the maintenance process

2. The HMI: PSM071WA

Adopt 32 bit RISC chip, more fast

The memory unit can be used to transfer pictures conveniently on the spot

Replaceable back light, to achieve a long life

Ensure suitable environmental resistance comparable to IP65F

With multicolor display graphics, it is more convenient to observe several data

Pop-up window function, effective use of the screen

Alarm function, immediately master the error content, improve the machine running condition

The number of memory tables is twice as large as before

Standard configuration has three communication ports, easier to use

3. Frequency converter: VFT

Power range from 0.1kW to 300 kW

4. The conclusion

The system is being put into trial operation, and the system is running well at present. The system performance is stable, easy to operate, easy to maintain, the system speed, tension, pressure and precision and dynamic response can reach the design requirements.

[scan]

[scan]