Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

1. The introduction

The deboiling-bleaching combined machine belongs to the pre-treatment equipment of dyeing and finishing equipment. Its main function is to remove all kinds of impurities (such as paddle material, oil agent, pollutants, etc.) on the fabric by chemical method, so that its surface is clean and its natural luster is presented, which is convenient for subsequent processing. De-boiling and bleaching machine includes three parts: desizing, scouring and rinsing.

The whole machine adopts frequency converter as the driving equipment, and the transmission points are about 30 ~ 60. Using elastic frame as tension feedback, each frequency converter can be simple tension control, the specific way is the frequency converter itself regulation or synchronous controller control. The desiccating and bleaching machine adopts communication control mode, which can set multiple datum points for segmenting operation to realize self-adaptation of running speed.

2. Process flow

Into the cloth pre - washing dipping bleach after washing drying Out of the cloth

3. WinMO product overall solution and its advantages:

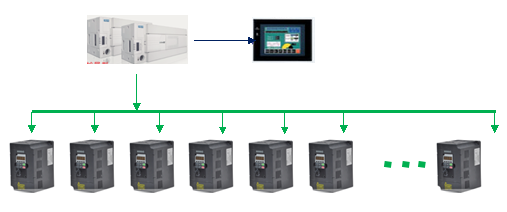

Boiled bleaching back control system USES a DPH rammasun PLC as the core, in a way that is DeviceNet bus way instead of analog control frequency converter, according to the requirements of tension line speed distribution and real-time control, reduced the field go line, improve the control precision, save a lot cost, has brought tangible benefits to the customers.

The feeding and discharging units are frequency converter VFT0022T4. Pre-wash for inverter VFT0037T. The frequency conversion of the first three washing boxes, the rinsing after impregnation and the last four washing boxes is composed of VFT22T4. The bleaching process consists of variable frequency VFT0055T4 in a steel-track steam-tank. The drying process is completed by 3 sleeve dryers as VFT0075T4

4. System configuration

1) PLC DPH

Fast processor, only 0.1μs for basic instructions, more than 0.3μs for special instructions

Can support 320 point switch

DPH type has the function of 4 in and 2 out of simulation, resolution ratio is 1/12000

Standard equipped with 4-axis high-speed counter function (single-phase 100kHz/phase 50kHz) and 4-axis 100kHz high-speed pulse output

USB parallel port is standard

Serial communication port can be freely selected RS-232C, RS-485 (2 port)

Support HostLink, NT Link, Compobus/S, DeviceNet, Profibus-DP, ControllerLink, Ethernet, protocol macro, Modbus-RTU and other communication methods and serial PLC connection function (up to 9 sets)

Support the extension unit of DPH series PLC

Rich instruction language, including PID, floating point operation, trigonometric functions, etc.

2). Frequency converter: VFT

Vector control

Support RS-422/485 communication (Modbus protocol)

Support for Compobus /D(DeviceNet) fieldbus

Easy to operate (frequency setting knob is provided on the operation panel)

Provide PID adjustment and energy saving control

Multi-stage speed adjustment (16 speeds)

3). Network system: DeviceNet

DeviceNet is a field network with excellent construction performance, covering a wide range of applications, from the sensor layer to the component layer to the controller layer. Various control devices, such as PLCs, robots, sensors, and actuators, can be conveniently connected to a single network. This will be able to reduce costs and save time in the design and manufacture of equipment and production lines, installation, commissioning, maintenance and other aspects of the manufacturing site. Further added value for PLC and SCM countermeasures can be provided to customers through a seamless connection to the master station network. With 64 nodes connected, speed limits up to 500Kbps, and communication distances up to 500M, DeviceNet creates many advantages for development and design, production and start-up, operation and maintenance. It has a variety of compatible components, can be easier to build the system; Device modularization at the slave station reduces assembly and wiring times, prevents wiring errors, and enables more compact control panels and equipment. The simple setup and communication work of DeviceNet software reduces startup time; The ability to collect data from components to aid in preventive maintenance, thereby preventing sudden system crashes and improving operation speed; The connector can be used for simple plug and replace components without stopping the system.

5. Conclusion

De-boiling and bleaching machine adopts advanced fieldbus communication technology, multi-motor synchronization technology without tension sensor and man-machine interface technology with control technology of time-sharing and multi-task operating system. It is the application of these automation technologies that makes the equipment run stably and reliably since it was put into production, without any failure affecting production.

[scan]

[scan]