Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

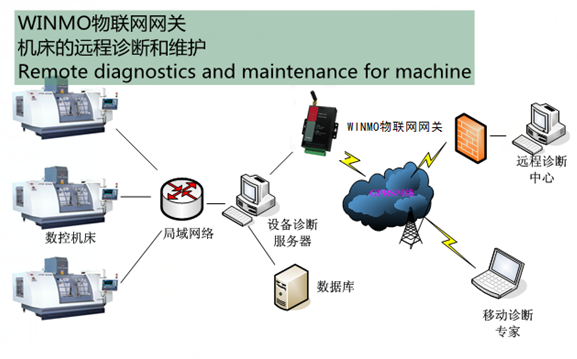

The fault diagnosis system of CNC machine tool is established by using wireless communication, so that the remote technical center can communicate with users through the network, and understand the working state of CNC machine tool, and use the interface technology of database to call the content of the database to diagnose the fault of CNC machine tool, and put forward the feasible solution.

A. The background,

CNC machine tool is the key production equipment in the processing line of each enterprise. If there is a failure, and the maintenance can not keep up with it in time, its long shutdown will bring huge losses to the production.

No matter how high the reliability of CNC machine tools, its failure is inevitable, so the user is most concerned about how to diagnose in advance when the equipment failure signal and how to timely repair after the failure.

Numerical control machine tool is a set of mechanical manufacturing, computer, hydraulic, sensing, information processing, optical and mechanical technology in one of the mechanical and electrical integration products. In view of the complexity of CNC machine tools and the limited manpower reserves of enterprises, equipment maintenance must rely on external forces. Sometimes because of some small problems, it is necessary to let the machine tool manufacturers come thousands of miles away to the site for maintenance, resulting in high travel costs and waste of human resources. With the development of network technology, the emergence of fault diagnosis system based on network has solved the above problems well.

B. Solution:

The remote fault diagnosis technology of CNC machine tool is to combine the fault diagnosis technology of CNC machine tool with the computer network technology, establish the monitoring point on the CNC machine tool, collect the data of its running state, and establish the expert diagnosis center on the enterprise LAN and Internet, analyze and diagnose the running state of the CNC machine tool. It can make the fault diagnosis more flexible and convenient, and can effectively improve the accuracy of diagnosis and work efficiency, reduce maintenance time.

C. System Composition:

The main functional modules of the system are: data acquisition module, data transmission module, network diagnosis service program and status monitoring and remote diagnosis software.

1. Data acquisition module: collect operation data, parameters and fault related information codes of CNC system.

2. Data transmission module: the collected operation data and parameters are sent to the remote diagnosis center. Here, we propose to use the gateway of the Internet of Things based on the GPRS network as the data transmission module. For complex faults, expert diagnosis should be made by combining video information.

3.fault query and diagnosis module: according to the current fault position or fault phenomenon of the machine tool, through the Web access mode, combined with the machine tool manufacturer available information, you can query the cause of the fault and processing methods, so as to realize the CNC system for simple fault query and diagnosis.

Winmo IoT gateway provides reliable wireless networking and remote data transmission functions for machine tools in this system. The communication between the equipment and the remote center is not limited by the distance. The patented anti-drop line mechanism enables the equipment to be online 24 hours a day to ensure smooth communication. Support different brands, different communication protocols of a variety of machine tools and equipment unified access. Multi-level user rights security management, network management function to achieve worry-free monitoring, reliable communication links for the remote maintenance of equipment to provide reliable protection.

Four, economic benefit analysis:

With the remote mechanical diagnosis and service system, CNC machine tool users can:

1. Effectively utilize external expert system to reduce machine downtime and improve production efficiency.

2. the realization of predictive maintenance, early detection of hidden trouble.

3. Reasonably predict the service life of the machine tool, so that the machine tool can be extended in service under the condition of quality and production.

4. Remote mechanical diagnostics and services can also bring many benefits to machine tool manufacturers

5.reduce service personnel and costs;

6. Conveniently track the quality of the machine tool, find the weak links, and constantly improve the quality of the machine tool;

7. State management of equipment to achieve the organic integration of post-maintenance, planned maintenance and predictive maintenance.

8. Establish long-term and close relationships with users.

[scan]

[scan]