Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

Industrial boiler is an important basic equipment in national economic construction and people's life. It is widely used in various aspects such as factory power, building heating and people's life. It is also a large consumer of energy and an important source of pollution. China has a large number of coal-fired industrial boilers, with wide distribution, high energy consumption and heavy pollution. Compared with developed countries, the overall level of energy efficiency lags far behind, and the potential of energy conservation and emission reduction is huge. Industrial boilers are the major energy consumers and important pollution sources in China, and the total energy consumption accounts for 30% of the national coal consumption. At the end of the eleventh five-year plan, the average operating efficiency of China's boilers is about 65%, which is 10% to 15% lower than the international advanced level. In order to keep the boiler running healthily, it is necessary to strengthen the daily running condition monitoring, and to deal with and adjust the running mode at any time.

Winmo customer, is an energy management and monitoring system integrator, providing boiler intelligent monitoring and after-sales service management system services. In the recent boiler project run by the customer, the geographical location of the boiler is relatively scattered, among which the mobile boiler needs to change its geographical location at any time according to the change of specific tasks, so the GPRS transmission mode is the most suitable.

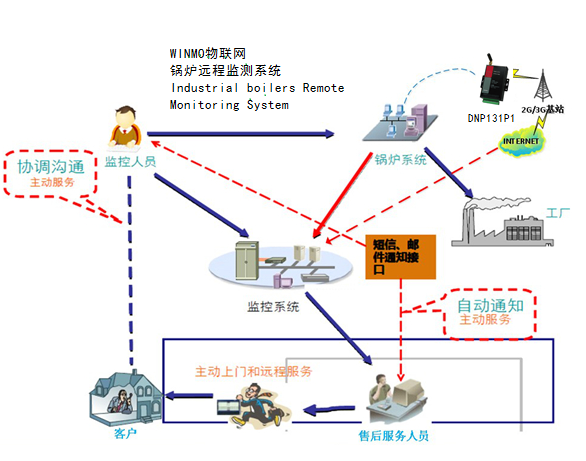

In the industrial boiler installed on the temperature, pressure, smoke, water hardness and other sensors, as long as the boiler starts, these sensors will automatically collect various types of data boiler operation, and through the WinMO Internet of things gateway, connected to the wireless network real-time transmission to the customer's remote monitoring center. The management center analyzes the real-time curve, histogram, pie chart display and data report of the monitoring indicators provided by the system. Once any abnormality or deviation is found in the operation data, the system will automatically send emails or information to the after-sales service personnel to timely provide "treatment" programs for the equipment with abnormal operation.

System topology diagram:

Site drawing of client project:

\

[scan]

[scan]