Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

Abstract: Now cutting machine has been very popular, there are all kinds of cutting machine on the market, some use manual operation, some use single-chip microcomputer control, some use PLC control, considering the cost performance and stability, this application program using Winmo DPE motion control PLC to achieve the control of EPS foam cutting machine.

One. list

Using servo or stepping two axis drive, the foam is cut into various patterns.

Two, working principle and use method

1. Using WinMO PLC and HMI, servo or stepping, to form a fixed electrical control system. Use the heater to heat the heating wire.

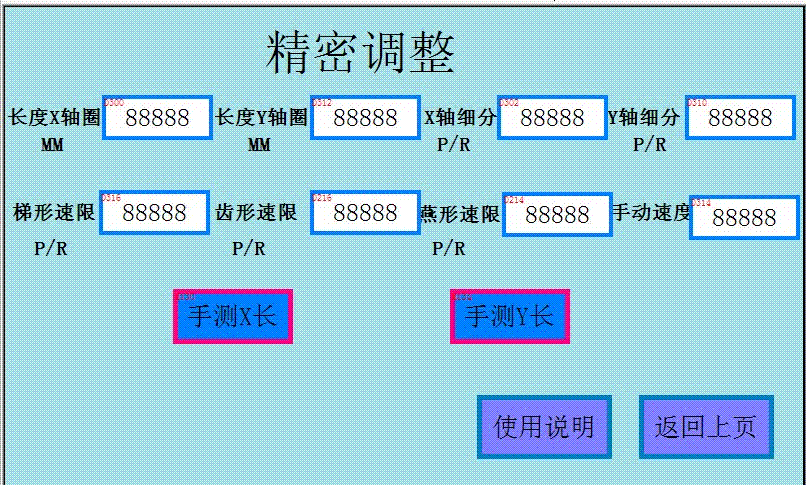

2. Set the parameters required for each graph on WinMO HMI, and use WinMO PLC to send pulse to control the movement of X axis and Y axis of the platform to cut each graph.

3, the use of WinMO PLC high-speed pulse Y0 and Y1 with the graphics to achieve a more accurate effect, and the use of servo drive, the speed is more ideal.

4, set the middle stop function, the graph does not reach the end can be suspended.

Three. System components and structure description

1. Drive part: servo or step drive.

2. Worktable part: controlled by Winmo HMI, the X axis motor drives the heating wire to move through the controller, the Y axis controls the heating wire to move up and down, and the moving distance is controlled by Winmo HMI system, the minimum reading is 0.1 mm.

3. Synchronization system: This machine is composed of X axis and Y axis according to the calculation requirements to form a proportional synchronization mechanism, simple structure, stable and reliable performance, high synchronization accuracy. Winmo HMI control values. The maintenance control PLC carries out calculation and transmission.

Four. Conclusion

A complete set of EPS cutting machine, including hardware, software design, for the control of WinMO PLC scanning time and performance are very high. In this paper, a brief introduction to the EPS cutting machine which is more important several parts, other details are many, no longer listed one by one. Using WinMO touch screen and WinMO PLC control system, stable performance, easy to use. Winmo touch screen and PLC in this machine is very high evaluation.

[scan]

[scan]