Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

(1) Introduction

The upper and lower die are respectively fixed on the upper and lower worktable of the folding bed, and the relative side of the worktable is driven by hydraulic transmission, and the shape of the upper and lower die is combined to achieve the bending and forming of the plate.

(2) Working principle and use method

A. Switch on the power supply, open the switch on the control panel, and then start the oil pump through HMI, then the sound of the oil pump rotation can be heard. (The machine does not act at this time)

B. travel adjustment, use must pay attention to adjust the travel, must be tested before bending. It must ensure that there is a gap of plate thickness when the upper die goes down to the bottom, otherwise it will cause damage to the mold machine. The adjustment of travel can be made quickly by using the formula function of HMI.

C.the selection of the bending groove, generally choose the groove of 8 times the width of the thickness of the plate.

D. Press the HMI switch to start bending. Different from the plate shearing machine, the bending machine can be switched randomly and stop if you want.

(3) Description of components and structure of the machine tool

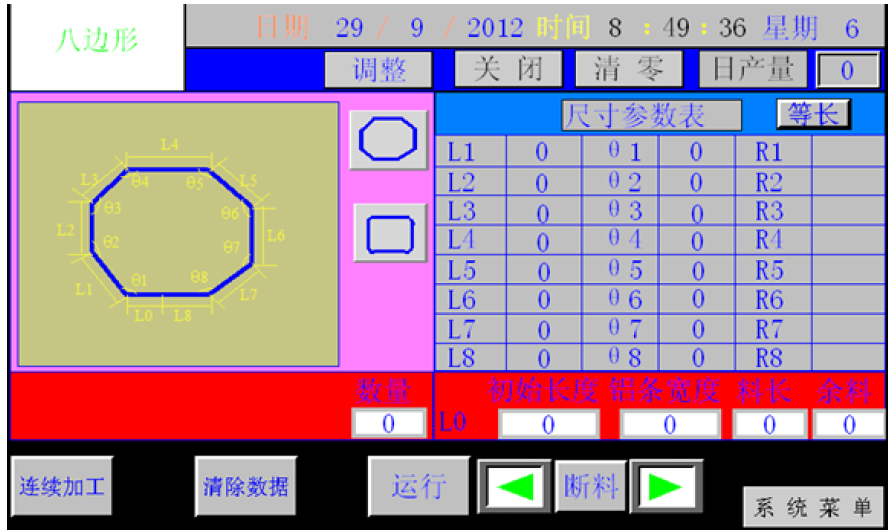

A. Sliding part: it adopts hydraulic transmission, and the slider part is composed of slider, cylinder and mechanical stopper fine-tuning structure. The left and right oil cylinders are fixed on the frame, and the piston (rod) drives the slider to move up and down through hydraulic pressure. The mechanical block is controlled by HMI to adjust the numerical value.

B. Worktable part: controlled by HMI, the motor drives the block frame to move forward and backward through the controller, and the moving distance is controlled by the HMI system. The minimum reading of the device is 0.01 mm.

C. Synchronization system: the machine is composed of torsional shaft, swing arm, joint bearing and other mechanical synchronization mechanism, simple structure, stable and reliable performance, high synchronization accuracy. The mechanical block is adjusted by the motor, and the value is controlled by HMI.

D. Pending mechanism: Pending mechanism adopts motor drive, which drives two screw rods to move synchronically through chain operation, and the size of stopping material is controlled by numerical control system.

(4) the conclusion

A complete set of bending machine, including hardware, software design, covering a wide range. In this paper, a brief introduction to the more important parts of the bending machine, other details are many, no longer listed one by one. Using touch screen control system, stable performance, design and easy to use. Winmo touch screen features complete, reliable and durable, simple programming, compared with other HMI products, friendly interface, to the user programming and maintenance have brought great convenience. In short, WinMO touch screen in the slitter design has played a key role, to your design work to bring great convenience, with the continuous improvement of WinMO touch screen performance, its application in the slitter will be more extensive and in-depth.

[scan]

[scan]