Winmo (Shanghai) Automation Technology Co.,Ltd. website!

021-51097178 13501931621 15221778690

021-51097178 13501931621 15221778690

【 Abstract 】 This paper mainly introduces the WinMO automation products in P-25T wireless brush carbon molding control scheme

【Bright spot】

1. Winmo DPH series PLC powerful expansion can, high-speed counting applications;

2. Winmo VFT series inverter application in complex environment;

【 Key words 】PLC HMI Inverter High speed counting Powder die-casting

【Preface】

As an important part of powder metallurgy industry, powder die-casting machine plays an irreplaceable role. P series press is suitable for automatic dry pressing of powder metallurgy, carbon, fine ceramics, magnetic materials and industrial powder products.

【Text】

The electronic control system of the tunnel oven system is mainly composed of three parts: mechanical CAM, encoder positioning and pressure control, which make it meet the following technological requirements:

◆Linear pressure, uniform powder density, high pass rate;

◆Molded embryonic parts stepless speed regulation

◆Automatic filling, loading, unmanned duty

◆Double feeding to ensure high consistency of embryo parts;

◆Visible mechanical transmission, intuitive fault information, low maintenance cost

【System structure】

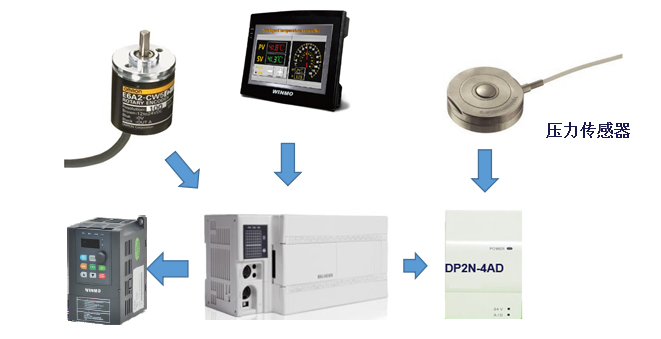

1、HMI:PSM071WA

2、PLC: Host DPH60Y24R+AD module DPH-4AD

3、Inverter: VFT series high performance non - inductive vector inverter

【System specifications】

Winmo DPH60Y24R high performance PLC as the control core of the system, through the high-speed input function, the realization of the real-time position of the mechanical CAM dynamic reading, high-speed interrupt output mechanism, to ensure every accurate die-casting.

The 4AD extension module is used to realize the on-site pressure reading. With the process algorithm, the consistency of the blender density and the safety of the die casting system are highly guaranteed.

The frequency converter is used to diffuse the complex environment of the metal powder, which is not only for the stability of WinMO frequency converter, but also for the die casting host to provide smooth torque, to provide constant power for the die casting.

Finally, combined with the WinMo PSM series man-machine interface, the dynamic state monitoring, fault troubleshooting and other functions of the equipment are realized. Provide convenient reference basis for customer production statistics and equipment maintenance.

[scan]

[scan]